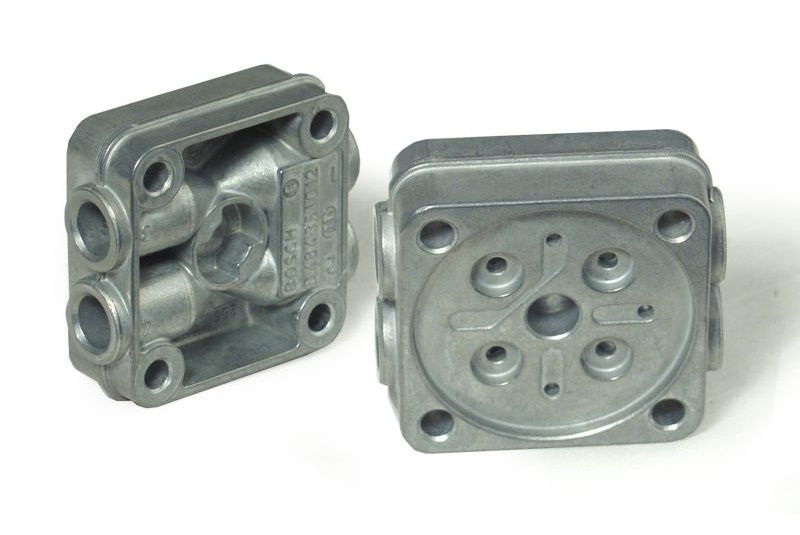

Zinc-alloy - ZAMAK - Die-casting

Die-casting foundry of HOBES Slovakia, s.r.o., produces wide range of technical zinc-alloy (zamak) castings for various branches of industry - automotive, furniture etc. Based on your requirements our production engineers, quality controllers and production staff will prepare full optimal process of die-casting which will enable to manufacture your products in required quality at acceptable price effectively.

In next stage we can produce for you optimal dies, die-cast and deliver the required parts. We own wide range of casting machines and machine tools therefore we can quickly react to your requirements for production of various castings, different in sizes and production series that may require post-casting machining. If surface treatment of your parts is required it is only natural we shall provide it.

Our main advantage is flexibility and excellent quality at acceptable price.

| Oddelenie | Typ stroja |

|---|---|

| Department of Equipment List | 1x solid edge |

| Die Casting | 2x LS3 – Zinc Hot Chamber Stroj union |

| 1x DAW5 - Zinc Hot Chamber Frech | |

| 1x DAW 20 - Zinc Hot Chamber Frech | |

| 1x DAW 80 - Zinc Hot Chamber Frech | |

| 1x DC30 - Zinc Hot Chamber LK Machinery | |

| 1x OLZ55 - Zinc Hot Chamber Oleopress | |

| 2x ZNT66 - Zinc Hot Chamber Techmire | |

| 1x CLTA63 - Zinc Hot Chamber Del Casting | |

| 1x IDRA80 - Zinc Hot Chamber Idra | |

| 1x DC88 - Zinc Hot Chamber LK Machinery | |

| 1x OLZ120 - Zinc Hot Chamber Oleopress | |

| 1x DAW125 - Zinc Hot Chamber Frech | |

| 2x DC130 - Zinc Hot Chamber – LK Machinery | |

| 1x baby plast 6/10P – plastic injection | |

| Die Casting Ancillary | 1x Automatic feeding machine Stroj union |

| Die Casting Process | Die Casting Process Equipment |

| 3x Oil Recirculating Units: Die Cooling/Heating | |

| Melting Department | 1x furnace 150 kg Zn /h + zinc pump + ingots moulds |

| Trim Department | 1x IDRA 120kN - hydraulic press |

| 1x EBU 5 - excenter press | |

| 1x MABU - excenter press | |

| 2x HARE 5 BS - hydraulic press | |

| Machining Department | 1x HV30 –drilling machine |

| 1x B17 drilling machine | |

| 1x HOB – 01 –tapping | |

| 1x HOB – 02 –tapping | |

| 1x THEISEN special purpose | |

| 1x special purpose 296.135 | |

| 1x special purpose 296.2xx | |

| Finishing Department | 1x GG-40 - shot blasting machine |

| 1x ROSLER R220EC –tumble grinding | |

| 1x ESPIRAL A350 – tumble grinding | |

| 3x OS3A - barelling | |

| 1x TRS 571-2 - annealing furnace | |

| 2x GUDE/BOW –abrasive-band grinding machine | |

| Quality Deparment | |

| Assembly Department | 1x KOVOPOL NJ-6 - riveting machine |

| 1x pneumatic screwdriver | |

| 1x special purpose pneumatic assembly machine | |

| Tool Room | 1x ECOSON - ultrasonic cleanerd |

| 1x SUI 32 - lathe | |

| 1x FUS 22 - milling machine | |

| 1x BRH – 20.02 - grinding machine | |

| 1x BHU 25 - grinding machine | |

| 1x hand tools for tool polishing |

| DESCRIPTION | VALUE |

|---|---|

| Number of Machines | 14 |

| Clamping force rang | 3 - 130t |

| Casting weights | 3 - 500g |

| Die Sizes | 80 x 160 x 80mm až 620 x 620 x 500mm |

| Material | Z410 |

| Castings for | automotive, furniture, electrotechnic, industrial utensils |

| Certification | ISO9001 |

What we do

We have three main production programmes: mortise door locks, zinc-alloy die-casting and stainless steel garden furniture.